Hardware & Tools

Description

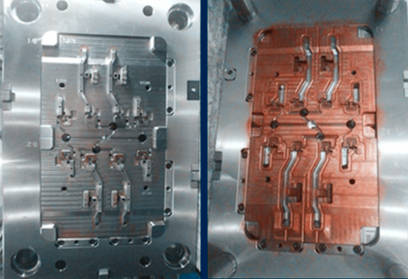

Different plastic injection mold design will lead to different result. suitable thickness in your part is very important. usually we use mold flow simulate the plastic injection molding process. in this way ,you can found more Potential problem. for example, reduce the cycle time of plastic injection molding and material. also, try to simplify your part and avoid unnecessary undercut. as we all know, the more complex you make the mold,the high the price you will cost.

Aco Mold have over 15 years of experience in the mold making and mold design industry. We& acute;ve worked on the shop floor, been a designer for a number of years and have been design manager for the last 5 years.

There is very little unemployment for anyone with technical skills (especially those where a 4 year degree is required). Plastic injection mold companies that make high quality products and treat their employees well attract candidates. Managers that are push their people too hard should keep in mind that employees have choices. Follow Aco Mold on Facebook.

Read More

Aco Mold Manufacturing

Plastic Injection Mold China

Address: No.7 fuhai fuyong,

Shenzhen, Guangdong

China, 518000

Tel: 0086-517-8689 5586

Fax: 0086-517-8689 5585