Cast & Forged

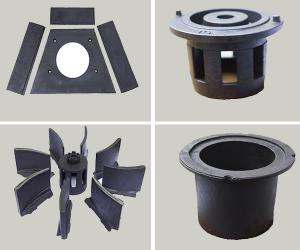

Description

1. With investment casting method for the production of Carbon steel cast iron, alloy steel, high chromium cast iron, heat-resistant alloy, stainless steel, precision alloy, permanent magnet alloy, bearing alloys, copper alloy, aluminum alloy, titanium alloy and nodular cast iron.

2. investment casting weight mostly tens of grams to several dozen kilograms, the company produced generally in about10 kg, heavy pieces are not easy to mass production.

According to the different shell materials, investment casting can be divided into: silica sol casting process; Sodium silicate casting process; composite casting process.

Kaitai casting technology is composite casting process,surface quality is slightly lower than silicasol technology,but greatly better than sodium silicate casting technology,price has advantages too,greatly lower than silicasol technology,slightly higher than sodium silicate casting technology.

Features: 1 casting shape is complicated, the casting can cast the smallest hole diameter up to 0.5mm, casting the minimum wall thickness of 0.3mm.2 casting surface quality, high size precision, reducing machining.3 suitable for mass production, high production efficiency.4 castings the production of a wide range, widely used in auto parts, machinery parts, engineering accessories, valve pipe production.

We can assure you the steady quality, punctual delivery and technical services.

Read More

ShandongKaitaiIndustalTechnologiesCo.,LTD

steel shot ball,surface cleaning, long life

Address: qingyang roda,zouping xian,bizhou city,shandong province,China,

binzhou, shandong

China, 257217

Tel: 0086-18706635002

Fax: 0086-0531-88939861