Plastics & Products

Description

Engineering for molding

Bepower Mould begins every mold design with our customer& acute;s needs in mind. Our team with 28 skilled engineers has experienced every category of custom mold in the marketplace today.

Let us design your part or give us a sample of what you want us to create; we can then create a working plastic model of your part using the latest technology.

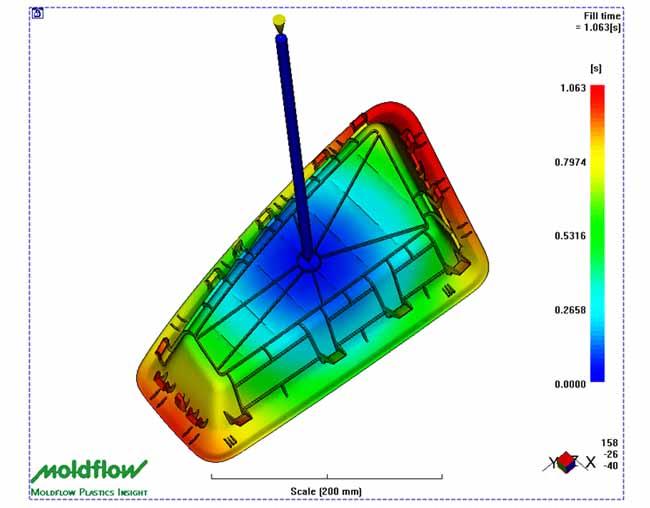

Moldflow allows us to optimize the part design, mold design and manufacturing processes.In order for high quality mold, we can use simulate or moldflow software to analyze the mold design before fabrication. We can find out and resolve potential problems in advance.

General Capabilities CAD Modeling (2-D, 3-D)

Design

Engineering

Inspection

Testing

Tool History Documentation

Technical Support

File Formats AutoCAD (DWG)

DXF-Drawing Interchange Format, or Drawing Exchange Format

IGES---Initial Graphics Exchange Specification, ANSI file format.

PDF---Portable Document Format

Pro-E or Pro/Engineer / Creo (DRW,PRT)

SolidWorks (SLDPRT,SLDDRW,SLDDRT)

STEP---Standard for the Exchange of Product Model Data

Read More

Previous

Plastic Parts Molding...

Bepower Mould Co., Ltd

Auto Parts Molds, Plastic Injection Mold, Die Casting Mold, Plastic Parts, Die Casting Parts Molding

Address: The 3rd Industrial Zone, Tiantou Hengli Town, Dongguan City, Guangdong P.R. China.,

Dongguan, Guangdong

China, 523478

Tel: 86 755 27911538

Fax: 86 755 27911538